| Power [W]: | 400 W |

|---|---|

| Construction form: | Straight |

| Chuck: | Quick-changing chuck SW12 (J2) |

| Start: | Direct air inlet, Push-to-start |

| Current: | Pneumatic |

Product number:

46100000

TG12/25D-SW12 Tapper SW12 and Screwing-in Tool

Applications

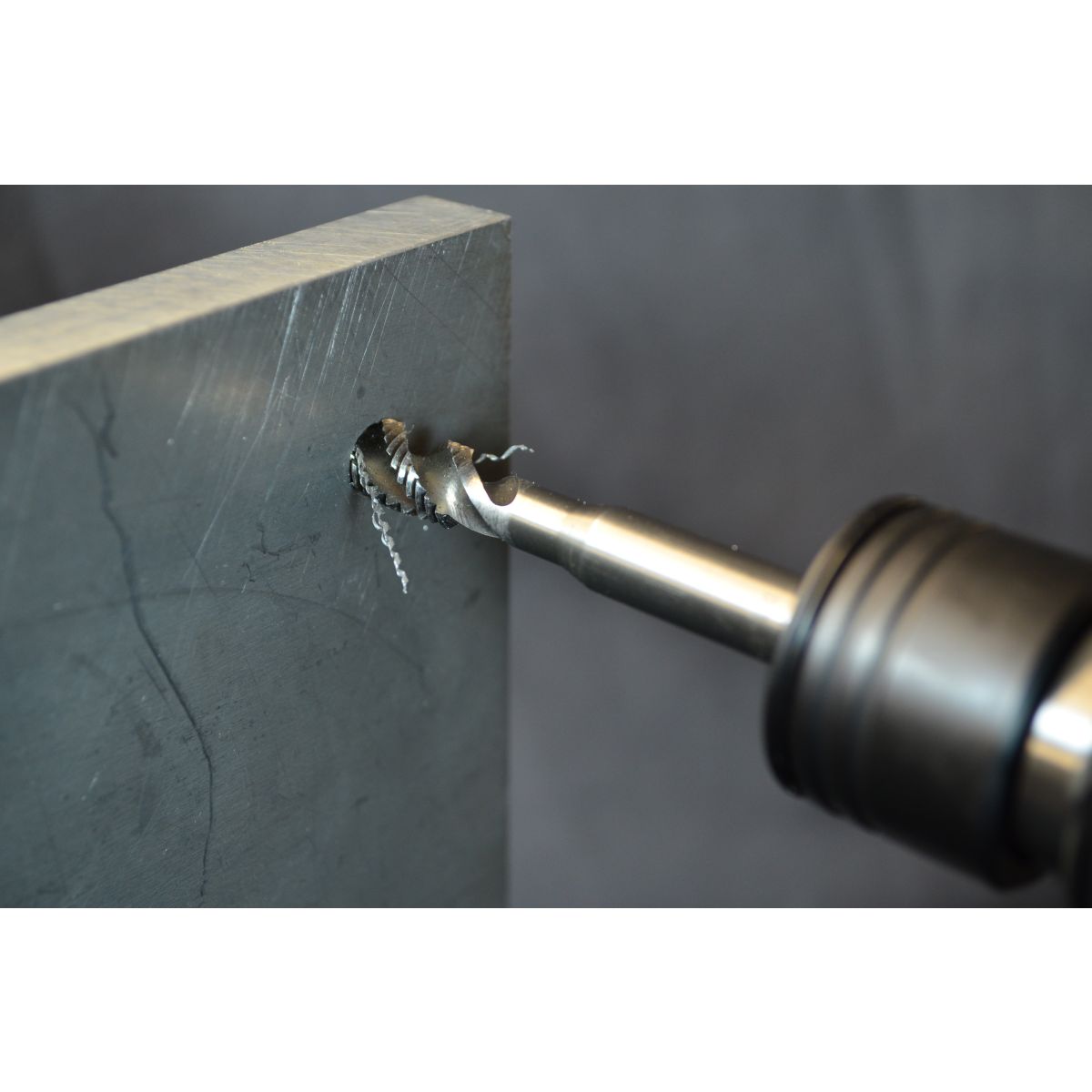

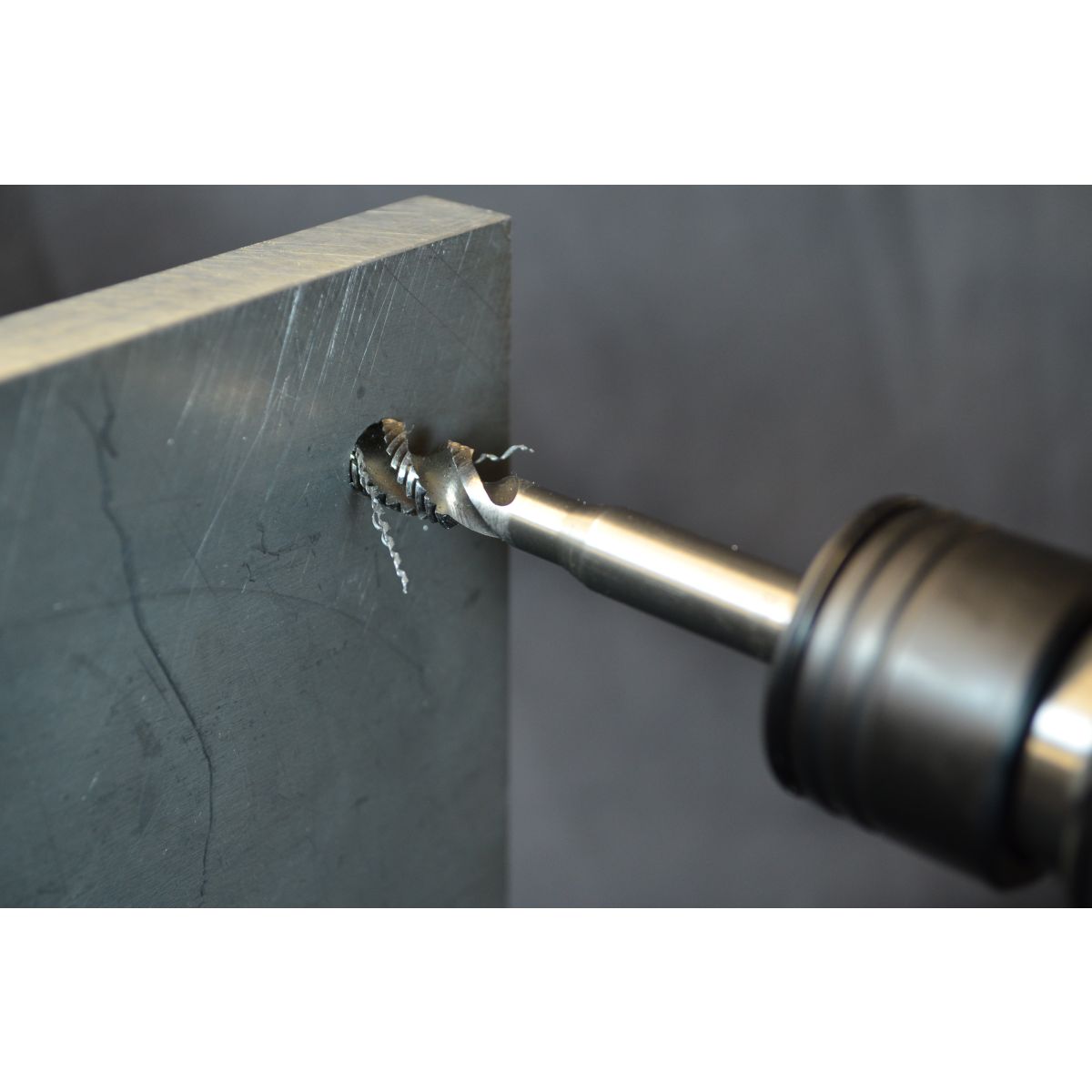

The Compressed Air Tapper TG12/25D-SW12 with direct air inlet and quick-change chuck SW12 is a tool for tapping with standard holders or in combination with a socket setter for screwing in sockets. This type is designed for mounting on a linear arm in the production area, the control is done via the direct inlet. Materials such as plastic, wood, aluminium, bronze, brass, cast iron as well as alloyed and unalloyed steels can be machined. The tapper is used in the metal industry, car body construction, plastics processing, the wood industry, in apparatus and container construction as well as by repair stores.

Compressed air tapper TG12/25D-SW12 with direct air inlet - for assembly into linear arms

With quick change chuck SWF-SW12Cuts thread into:

Alloy steel: max. Ø max. 10 mm

Cast iron, unalloyed steel: Ø max. 12 mm

Aluminium, brass, bronze: Ø max. 14 mm

Also suitable for screwing in threaded sockets

With direct air inlet for assembly with a linear arm

Quick changing of the tap holder/tapper

Long service life with high performance.

Oil-free operation possible

Select the straight design for working in vertical direction. The air tapper is started comfortably via axial pressure. Switching on at low speed makes it easier to place the tapper on the previously placed core hole. The tool is reversible, which can be achieved by pulling the tool. The return is at double speed, thus ensuring efficient work, especially during the production process.

The holder is a quick-change chuck SWF-SW12 for standard holders. Select the desired tap holder from the accessories, it is not included in the delivery. It must be selected according to the used tap insert. Optionally, the holder can be equipped with a thread socket setter for screwing in thread sockets and stud bolts, which are frequently found in furniture manufacturing or engine construction, for example. Please contact us, we will be pleased to advise you for a perfectly fitting combination.

| Power [W]: | 400 W |

|---|---|

| Construction form: | Straight |

| Chuck: | Quick-changing chuck SW12 (J2) |

| Start: | Direct air inlet, Push-to-start |

| Direction of rotation: | Reversible |

| Speed: | 220 / 470 min-1 |

| Thread Steel max. Ø: | 12 mm |

| Length: | 335 mm |

| Housing Ø: | 46 mm |

| Weight: | 1.87 kg |

| Recommended hose Ø: | 9 mm |

| Air consumption: | 11 l/s |

| Sound pressure level: | 78 dB(A) |

| Current: | Pneumatic |

| Working pressure: | 6.3 bar |

| Information: | Useable as screwing-in tool |

| Inlet air connection: | G 1/4" |

| Vibration: | < 2.5 m/s² |

Included in delivery:

Tool withquick-changing chuck SW12, hanger, second handle.

Tap holder is not included.

Options